Showroom

Spray drying is a process that can be done only in our Spray Dryers. The method is for making a dry powder out of slurry or liquid by quickly drying the material with a thermal gas. Further, this is the considerate technique of drying numerous heat-sensitive material, for example, pharmaceuticals and foods.

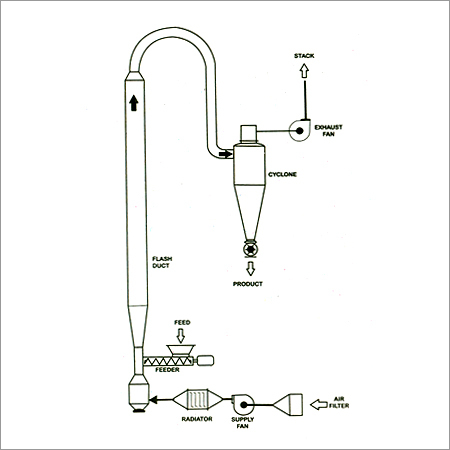

We are gaining immense appreciation from our customers for offering qualitative range of Flash Dryers. They help in serving various application in varied industries. The dryers have tough structure and can perform with same efficiency for many years.

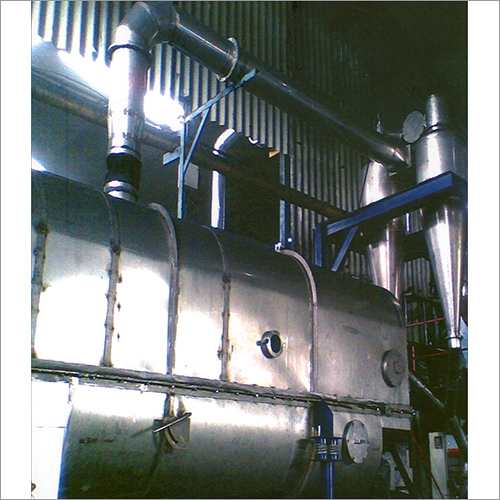

Material handled in our Fluid Bed Drying Plant float on gas or air cushion. The treated air is delivered to the bed via an orificed distributor plate and then floes via solid bed at enough speed to support the particles weight in liquidized state. Bubbles collapse and dorm in our bed of material advancing intense particle movement.

Buy from us compact and versatile laboratory spray dryer for your pharmaceutical, food or any other industry. Get this one in your industrial laboratory to meet your spray drying needs. Moist powder can be dried using this drying machine.

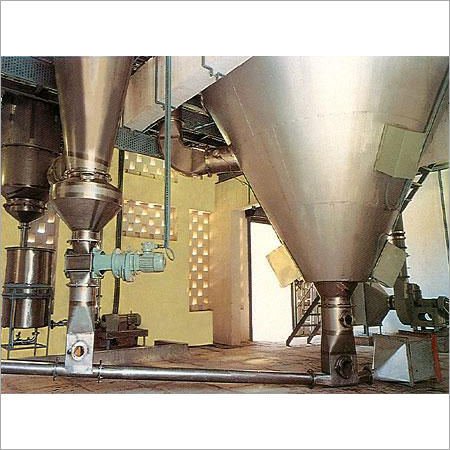

Spray Drying Plant And System designed by our team of skilled professionals are available in various different variants as per their working capacities. These are highly efficient and cost effective in operation as it requires very less maintenance.

Advanced Drying Systems is a big name which deals in the manufacturing and supplying of high performance Drum Dryer that are used for the drying of large amount of moist raw material to eliminate the watery content up to zero percent.

Film Evaporators are very efficient and made for doing various functions and carrying out various processes. These products are highly durable and made for being installed in the various industrial regions. They are large and require maintenance. These products are very easy to install as well as simple to operate.

The Rotary Dryer is situated at a slight flat incline to enable gravity to help with moving material via the drum. Further, as the drum pivots, lifting flights get the material and drop it via the air stream as to augment thermal exchange effectiveness. When operating with agglomerates, tumbling activity bestowed by the dryer provides the additional advantage of further polishing and rounding of granules.

Offered Rotary Atomizers can be availed in automatic and semi automatic mode based options. Available in standard design, these high speed systems are instrumental in disintegrating different substances into droplets. User friendly mechanism and reliable functioning are their key features.

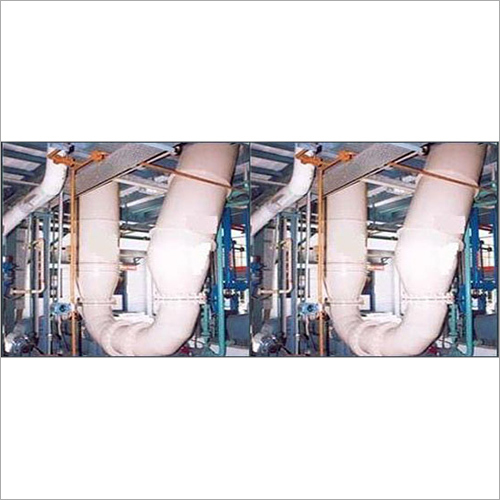

These low maintenance Air Dispersion Dryers are available in 250 cfm to 2000 cfm capacity range based option. Offered in tailor made specifications, these energy efficient equipments are appreciated for their impact proof design, corrosion protected structure and low maintenance cost.

Automatic Ring Dryers are available in 50 kg to 5000 kg capacity based option. Accessible in custom made design, these drying solutions are considered as better substitute of flash dryers. These pneumatic systems are effective in quick separation of dry and fine moisture particles through prolonged circulation technique.