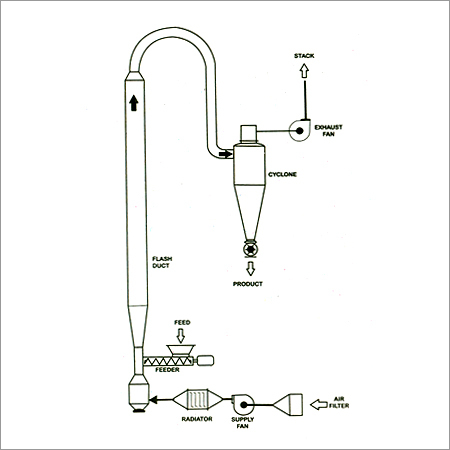

Vertical Flash Dryer

Product Details:

- Heat Source Steam, hot air

- Temperature Up to 400C

- Fuel Type Electricity, gas, coal or oil

- Power Consumption As per requirement

- Material Mild Steel / Stainless Steel

- Voltage 220V/380V/415V

- Technology Flash Drying Technology

- Click to View more

X

Vertical Flash Dryer Price And Quantity

- 1 Unit

Vertical Flash Dryer Product Specifications

- Steam, hot air

- Flash Drying Technology

- 220V/380V/415V

- Electricity, gas, coal or oil

- Customized as per application

- As per requirement

- Mild Steel / Stainless Steel

- Up to 400C

Vertical Flash Dryer Trade Information

- 1 Unit Per Month

- 3-4 Week

Product Description

We are the manufacturer of superior quality Vertical Flash Dryer which is best suitable for different kinds of coarse and fine materials such as fish meals, polymers, metallic powders, clays and pigments. It allows smooth functioning, reliability, easy installation, hassle free operation and robust construction. In addition to this, it can easily work at lower temperatures as it is integrated with high performance efficiency. Apart from this, the said product is widely appreciated due to its numerous qualities such as flawless appearance, low maintenance, anti-corrosive nature, compact size and light weight. This can be easily availed in diverse sizes, shapes and specifications based on the requirement.

Vertical Flash Dryer Specifications:

- Drying Chamber Size: 200 to 1600 mm

- Max Temperature: 450 Degree Centigrade

- Material:Stainless Steel

- Frequency: 50 Hz

- Voltage: 110 - 220 V

- Gross Power: 3 Kw

Advanced Flash Drying Technology

Our Vertical Flash Dryer utilizes state-of-the-art flash drying technology, enabling high-speed evaporation for particles as fine as 10 microns. Flexible in design, it supports both mild steel and stainless steel construction to accommodate the most demanding industrial drying needs. Automatically controlled via PLC systems, it delivers consistent and reliable results, regardless of the heat or fuel source used.

Customizable and Modular Design

The dryers vertical, modular installation adapts seamlessly to your production layout. Its dimension and airflow rate can be customized, ensuring optimal integration and process efficiency. The feeding and exhaust systems further enhance operational flexibility, supporting different product moisture contents and material types without compromising on performance or safety.

Effortless Operation and Maintenance

Engineered for minimal maintenance, the Vertical Flash Dryer provides easy access for servicing. With automatic overload protection, temperature control, and noise levels under 80 dB, it ensures safe, quiet, and continuous operation. The robust build resists wear while the PLC-controlled process simplifies adjustments and enhances uptime.

FAQs of Vertical Flash Dryer:

Q: How does the Vertical Flash Dryer operate for drying materials?

A: The Vertical Flash Dryer rapidly dries powders and granular materials by suspending them in a stream of hot air, causing immediate evaporation of surface moisture. The continuous, PLC-controlled process efficiently handles particle sizes from 10 to 500 microns, delivering uniform results.Q: What types of products can this flash dryer handle?

A: This dryer is suitable for a wide array of materials, including fine powders and granules, with a particle size range of 10 to 500 microns. Typical applications include food ingredients, chemicals, minerals, and pharmaceutical intermediates.Q: When is it ideal to use a vertical flash dryer instead of other dryers?

A: A vertical flash dryer is ideal when rapid moisture removal and high throughput are required, especially for heat-sensitive materials or for processes demanding customizable airflow and temperature control up to 400C.Q: Where can the Vertical Flash Dryer be installed?

A: Its modular, vertical structure allows installation in a variety of industrial settings. Customizable dimensions enable integration within existing process lines, making it suitable for both small and large-scale production facilities.Q: What is the process for customizing airflow and sizing of the flash dryer?

A: The dryers airflow rate and physical dimensions are tailored based on your specific application requirements, such as material characteristics, desired output capacity, and available installation space. Our engineering team consults closely with clients to ensure optimal sizing.Q: How is maintenance performed on the dryer, and what features simplify servicing?

A: Maintenance is straightforward due to accessible components and the low-maintenance design. The PLC system provides diagnostics, while powder coated or polished surfaces and overload protection ensure minimal downtime and reliable long-term operation.Q: What benefits does the PLC-controlled automation bring to the drying process?

A: PLC-controlled automation offers precise control over temperature, airflow, and operation sequences. This leads to enhanced product consistency, improved energy efficiency, reduced manual intervention, and comprehensive safety management throughout the drying cycle.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email