Rising Film Evaporator

Product Details:

- Pressure Up to 1.5 MPa

- Sealing Flanged Seal

- Condition New

- Process Continuous

- Power Source Electric

- Application Chemical, Pharmaceutical, Food Processing

- Material Stainless Steel

- Click to View more

X

Rising Film Evaporator Price And Quantity

- 1 Unit

Rising Film Evaporator Product Specifications

- Customizable

- 5 - 75 kW

- Electric

- Stainless Steel

- Up to 1.5 MPa

- Chemical, Pharmaceutical, Food Processing

- 1000-8000 kg

- 220-380 V

- Flanged Seal

- New

- Continuous

Rising Film Evaporator Trade Information

- 1 Unit Per Month

- 2-3 Week

Product Description

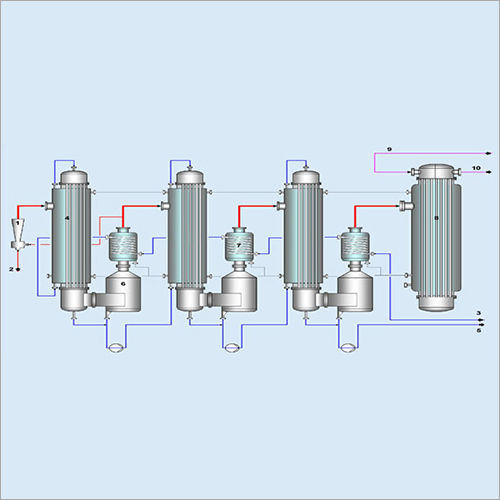

Rising Film Evaporator offered by our company, is designed by our experts using high quality raw materials. This evaporator is mainly used for evaporating the water from the products to dry them. This evaporator is widely known for its unique features like high quality, easy installation, rugged construction, less energy consumption, longer functional life, and flexible operation. It require very low maintenance and replacement costs. This evaporator is very effective as well as economical and safe to use. They are highly appreciated by people, in the market.

Versatile Evaporation Performance

With capacities ranging from 100 to 20,000 L/h and heating areas up to 300 m2, the rising film evaporator adapts seamlessly to both small and large-scale processing. The system operates on a continuous process powered by electricity and is suitable for applications in chemical, pharmaceutical, and food industries. Engineered for high efficiency, it delivers reliable concentration results, even with feed materials up to 30% and final product concentrations up to 75%.

Advanced Construction & Easy Maintenance

Crafted from durable stainless steel with a shell thickness of 5-16 mm, the evaporator features an internal mirror-like finish, ensuring product quality and easy cleaning. Maintenance demands are minimal, supported by the clean-in-place (CIP) method for effortless hygiene and system upkeep. Custom dimensions and installation types (skid-mounted or on-site erection) provide flexibility for different facility layouts.

Precision Control & Safety

Operators benefit from dual control options-PLC automation or manual management-enhancing operational precision. The shell-and-tube heat exchanger design maximizes heat transfer efficiency, while flanged seals and design pressures tailored to customer requirements ensure safe and dependable performance. The system functions with three-phase electric power and can be customized for voltage and pressure needs.

FAQ's of Rising Film Evaporator:

Q: How does a rising film evaporator work in continuous processing?

A: A rising film evaporator operates by evaporating volatile components from a liquid feed as it ascends inside vertical tubes, forming a thin film due to steam heating from the shell and tube heat exchanger. The continuous process ensures a constant inflow of feed and outflow of concentrated product, making it ideal for large-scale, uninterrupted operations.Q: What types of materials are compatible with this evaporator?

A: This equipment is primarily constructed from high-grade stainless steel, allowing safe and efficient evaporation of various liquids in the chemical, pharmaceutical, and food processing sectors. Its polished, internal mirror finish and CIP functionality make it suitable for handling both highly pure and viscous substances.Q: When should CIP (Clean-In-Place) cleaning be performed?

A: CIP cleaning should be conducted based on your process requirements, product load, and contamination risk-typically after each production batch or as prescribed in your maintenance schedule. This ensures optimal hygiene and system performance, reducing downtime and manual intervention.Q: Where can this rising film evaporator be installed?

A: The unit can be delivered as a skid-mounted package for ready integration into existing lines or erected on-site for customized installations. Its flexible design and customizable dimensions make it suitable for a broad range of facility spaces, from compact to expansive industrial plants.Q: What are the key benefits of using a PLC control system with this evaporator?

A: A PLC (Programmable Logic Controller) offers precise process control, real-time monitoring, automation of operational parameters, and quick adaptation to changing feed conditions. This enhances product consistency, operational safety, and energy efficiency, while reducing the risk of human error.Q: How is maintenance minimized with this system?

A: Maintenance requirements are reduced thanks to the system's robust stainless steel construction, smooth internal surfaces, and the inclusion of a CIP cleaning mechanism. This design prevents build-up and blockages, ensuring a prolonged operational life with minimal service interruptions.Q: What applications can benefit most from this evaporator?

A: Industries dealing with concentration or purification of heat-sensitive liquids-such as chemical manufacturing, pharmaceutical production, and food processing-will benefit greatly. The system's adaptability to variable feed concentrations and custom pressure/voltage requirements further broadens its industrial utility.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email