SS Spray Dryer

Product Details:

- Fuel Type Electricity / Oil / Gas

- Power Consumption 18 kW/hr

- Heat Source Electric / Steam / Oil Fired Heat Exchanger

- Temperature 150C to 250C

- Power 18 kW

- Material Stainless Steel (SS 304/316)

- Voltage 415 V

- Click to View more

X

SS Spray Dryer Price And Quantity

- 1 Unit

SS Spray Dryer Product Specifications

- Customizable

- 18 kW/hr

- Electricity / Oil / Gas

- 415 V

- 150C to 250C

- Electric / Steam / Oil Fired Heat Exchanger

- Stainless Steel (SS 304/316)

- 18 kW

- Spray Drying

SS Spray Dryer Trade Information

- 1 Unit Per Month

- 3-4 Week

Product Description

The offered SS Spray Dryer is made available by us in various commercial and industrial applications. The offered dryer is very effective and has a highly efficient and durable service life. The offered dryer is transformation of feed from a fluid state into dried particulate form by spraying the feed into a hot drying medium. It is a continuous particle-processing drying operation. The feed can be a solution, suspension, dispersion, emulsion or slip. The SS Spray dryer involving the conversion of fluid into fine droplets and exposing them to a hot drying media, so as to achieve defined dry particulate matter is spray drying.

SS Spray Dryer Technical Details:

- Material : Stainless Steel

- Max Temperature : 200 Deg C

- Power Source : Electric

- Frequency : 50 Hz

- Voltage : 230 V

- Power : 11 kW

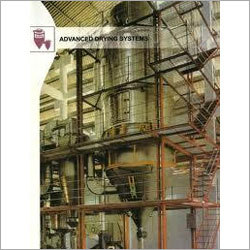

Advanced Spray Drying Technology for Industry Needs

The SS Spray Dryer utilizes innovative spray drying technology, enabling continuous, efficient transformation of liquids into fine powders. With customizable dimensions and capacities, it adapts readily to various production scales in pharmaceutical, food, chemical, and dairy sectors. Its robust, PLC/HMI-controlled system and polished stainless steel construction ensure reliability, hygiene, and consistent output quality.

Flexible, Efficient, and User-Friendly

Designed for flexibility, the SS Spray Dryer offers both rotary and pressure nozzles, along with selectable air flow regimes-co-current or counter-current. The CIP (Clean In Place) system simplifies cleaning and meets stringent hygiene standards. Its automatic or semi-automatic operation supports productivity, while skid-mounted installation streamlines setup in diverse facility layouts.

FAQ's of SS Spray Dryer:

Q: How does the SS Spray Dryer operate for continuous processing?

A: The SS Spray Dryer uses a continuous operation method where feed liquid is atomized via rotary or pressure nozzles and rapidly dried by hot air (electric, steam, or oil-fired). This process creates powder with controlled moisture content (3%-5%) efficiently, supporting uninterrupted production cycles.Q: What industries commonly use the SS Spray Dryer and why?

A: Industries such as pharmaceuticals, food, chemicals, and dairy regularly utilize the SS Spray Dryer due to its ability to produce uniform, high-quality powders, ensure product safety via polished SS construction, and facilitate strict hygiene standards with its CIP system.Q: When is the CIP (Clean In Place) system utilized during spray drying?

A: The CIP system is typically employed after each production batch or scheduled intervals to thoroughly clean the spray dryer's internal surfaces without dismantling, ensuring optimal hygiene and preventing cross-contamination, especially crucial in food and pharma applications.Q: Where can the SS Spray Dryer be installed, and what makes installation convenient?

A: Thanks to its skid-mounted design and customizable dimensions, the SS Spray Dryer can be conveniently installed in a wide range of factory or processing environments across India and internationally, allowing for flexible layout and easy relocation if needed.Q: What is the benefit of choosing a rotary or pressure nozzle in this spray dryer?

A: Rotary nozzles are ideal for high viscosity liquids and large capacities, while pressure nozzles offer finer particle size control in lower-capacity and precision applications. The choice allows customization of powder characteristics to meet specific industry requirements.Q: How is the moisture content in the dryer output maintained between 3% to 5%?

A: Moisture content is regulated through precise temperature control (150C to 250C), optimized air flow (co-current or counter-current), and adjustable nozzle settings, all monitored via PLC/HMI control, ensuring consistent product quality per batch.Q: What advantages does the PLC/HMI based control panel provide?

A: The PLC/HMI control panel delivers user-friendly, automated process management, real-time monitoring of critical parameters, and simplified troubleshooting, resulting in improved process control, energy efficiency, and reduced downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese