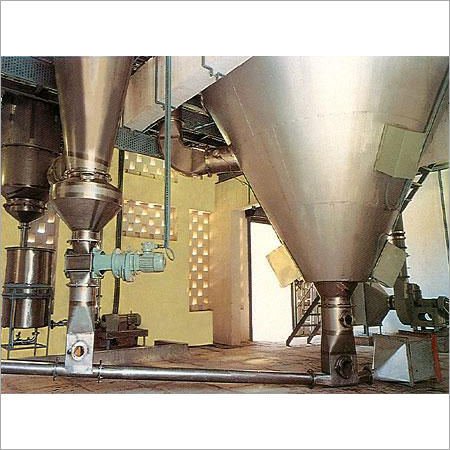

Spray Dryer Plant

Product Details:

- Power 45 kW

- Condition New

- Product Type Spray Dryer Plant

- General Use Industrial Liquid Drying

- Material Stainless Steel

- Weight (kg) 7000 kg

- Computerized Yes

- Click to View more

X

Spray Dryer Plant Price And Quantity

- 1 Unit

Spray Dryer Plant Product Specifications

- 45 kW

- New

- High Speed Mixer

- Yes

- Electrical

- Heavy Duty Electric Motor

- Industrial Liquid Drying

- 7000 kg

- 415V 3 Phase

- Spray Dryer Plant

- Available

- Silver

- Yes

- Customized

- Single/Double Option

- Stainless Steel

Spray Dryer Plant Trade Information

- 1 Unit Per Month

- 3-4 Week

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Daman and Diu, Lakshadweep, South India, Assam, Arunachal Pradesh, Bihar, Gujarat, Goa, Jharkhand, Maharashtra, Punjab, Rajasthan, Sikkim, Tamil Nadu, Tripura, Uttar Pradesh, Meghalaya, Manipur, North India, Delhi, Mizoram, East India, Jammu and Kashmir, Haryana, Nagaland, West Bengal, Madhya Pradesh, Karnataka, Telangana, Andhra Pradesh, Kerala, Central India, Odisha, West India, Chhattisgarh, All India

Product Description

We are leading the industry with our tremendous spectrum of Spray Dryer Plant. They are specifically designed under the guidance and support of our professionals to ensure the performing capability according to the set standards. The Spray Drying Plants are commonly used to remove or eliminate the presence of moisture from different products. The Drying Chambers can be installed without much difficulty and provide an easier operation. They have multiple adjustable features for an efficient functioning. The chamber offer great resistance against corrosion and do not require regular maintenance.

Spray Drying Plant Features:

- High performance

- Sturdy construction

- Durable finish standards

- Longer service life

Spray Dryer Plant Specification:

- Power source : 200 V three phase

- Power consumption : 5 KW

- Weight : 220 kg- 280 kg

Precision Engineering for Diverse Industries

Engineered to meet the rigorous demands of various sectors, our spray dryer plant excels in dairy, pharmaceutical, chemical, and food processing applications. Its modular design accommodates different product requirements and process conditions, ensuring efficient drying regardless of input. With customizable capacity, this system integrates seamlessly into both small and large-scale production environments.

Flexible Performance and Safety Controls

The spray dryer plant features flexible heating options (steam, electric, or gas) and supports both rotary and pressure nozzle types to cater to diverse operational needs. The PLC-enabled digital touchscreen panel delivers user-friendly operation, while built-in safety functions, such as overload and overheat protection, safeguard equipment and personnel during continuous, automatic processes.

Quality Construction and Ease of Maintenance

Crafted from high-grade stainless steel with a mirror-polished finish, the plant offers superior durability and hygiene standards. The units robust construction, easy cleaning features, and low-noise operation ensure a safe, efficient working environment, reducing downtime and supporting consistent product quality for exporters, manufacturers, and suppliers worldwide.

FAQs of Spray Dryer Plant:

Q: How does the spray dryer plant achieve uniform and efficient drying?

A: This spray dryer utilizes advanced rotary or pressure nozzles to atomize liquid into fine droplets, which are then dried quickly by hot air (up to 250C) in a concurrent or countercurrent airflow system. The uniform distribution of droplets and continuous airflow ensure consistent, rapid, and efficient drying, resulting in high-quality, free-flowing powders suitable for various industrial applications.Q: What are the main applications for this spray dryer plant in different industries?

A: The spray dryer plant is extensively used in the dairy industry for producing milk powder, in pharmaceuticals for powdered medicines, in the chemical sector for drying chemicals and catalysts, and in food processing for ingredients such as flavorings and additives. Its versatile design supports a wide range of industrial liquid drying processes.Q: When should maintenance be performed on the spray dryer plant?

A: Routine maintenance should follow the manufacturers recommended schedule, typically after set operational hours or production cycles. The plant is designed for easy cleaning and servicing, allowing quick access to key areas and minimizing downtime. Regular checks on the control panel, atomizers, and safety systems help ensure optimal performance and equipment longevity.Q: Where can the spray dryer plant be installed?

A: This plant is intended for industrial settings such as factories or production facilities in sectors including dairy, pharmaceuticals, chemicals, or food processing. Its customizable dimensions and robust build make it suitable for installation in newly built or existing manufacturing spaces, with electrical requirements of 415V 3-phase power supply.Q: What benefits does computerized and PLC-controlled operation offer?

A: Computerized and PLC control allows for precise monitoring and adjustment of process parameters through a digital / touchscreen interface. This automation ensures consistent product quality, streamlines operations, reduces human error, and enhances safety with real-time alerts for overload or overheating, ultimately improving productivity and ease of use.Q: How is operator safety ensured during spray dryer operation?

A: Operator safety is prioritized through integrated overload and overheat protection systems, low-noise operation (<85 dB), and fully enclosed stainless steel construction. The digital control panel displays real-time status and alerts operators to any operating anomalies, ensuring safe and controlled functioning at all times.Q: What is the advantage of using stainless steel with a mirror-polished finish?

A: Using stainless steel with a mirror-polished finish ensures superior durability, corrosion resistance, and easy cleaning, all of which are essential for industries with stringent hygiene and quality standards like dairy and pharmaceuticals. This finish also helps maintain product purity and extends the overall lifespan of the plant.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese