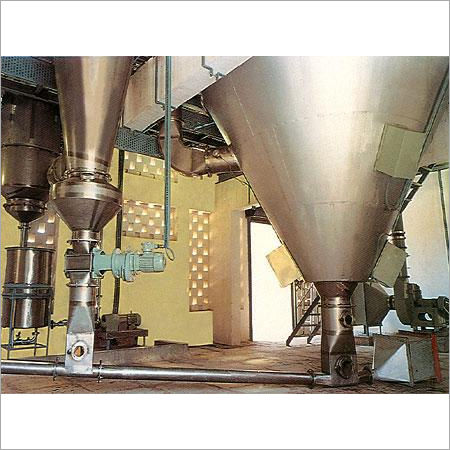

Spray Drying System

Product Details:

- Power 10 kW to 150 kW depending on model

- Condition New

- Product Type Spray Drying System

- General Use Powder Production from Liquid/Slurry

- Material Stainless Steel 304/316

- Capacity 50 kg/hr to 2000 kg/hr (customizable)

- Weight (kg) Varies as per model

- Click to View more

X

Spray Drying System Price And Quantity

- 1 Unit

Spray Drying System Product Specifications

- Customizable as per capacity

- New

- 10 kW to 150 kW depending on model

- Heavy-duty Stainless Steel

- Electric Motor Drive

- Silver

- Yes

- Stainless Steel 304/316

- Yes

- 50 kg/hr to 2000 kg/hr (customizable)

- Easy Operation, CIP System, Uniform Particle Size

- High Speed Centrifugal Atomizer

- Powder Production from Liquid/Slurry

- Varies as per model

- Yes

- Spray Drying System

- Industrial Grade, High-efficiency

- 380 V / 415 V, 3 Phase

Spray Drying System Trade Information

- Nhava Shevi

- 1 Unit Per Month

- 3-4 Week

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Sikkim, Manipur, Uttarakhand, Daman and Diu, Lakshadweep, South India, East India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Nagaland, Odisha, Punjab, Pondicherry, Tamil Nadu, Telangana, Tripura, West Bengal, All India, Uttar Pradesh, Rajasthan, North India, Andhra Pradesh, Kerala, Central India

Product Description

We hold specialization in offering a wide range of Spray Drying Systems with the support of our advanced manufacturing facilities. Made using high quality raw materials our Spray Drying Systems are used in various applications for the production of industrial chemicals, minerals, pigments, ceramic products, catalysts, salts and much more.Spray Drying Systems offers:

- Superior quality spray dryer technology product and service.

- Shortest new equipment

- All products are delivered on time

- Flexibility in tailoring the scope of supply

- Custom designed spray drying systems are offered

- Standard small scale spray dryers.

Specification Of Spray Drying Equipment:

| Power Source | Electricity |

| Design | Customized |

| Capacity | As per request |

| Automatic Grade | Automatic, Semi-Automatic |

Precision Drying for Various Industries

Our spray drying system offers precise powder production, suitable for pharmaceuticals, food, chemicals, dairy, ceramics, and dyes. With flexible spray pressure, atomization methods, and inlet/outlet temperature control, it ensures optimal results for batch or continuous operation. Customizable capacity and material options cater to diverse processing needs.

Smart Control & Safety Features

Equipped with a modern touchscreen PLC HMI, the system provides intuitive operation and monitoring. Advanced safety protections, including overload, over-temperature, and interlock systems, guarantee reliable and secure functioning. The CIP (Clean-In-Place) system simplifies maintenance for uninterrupted production.

FAQs of Spray Drying System:

Q: How does the atomization process work in this spray drying system?

A: The atomization process employs either a rotary disc or nozzle to disperse liquid or slurry into fine droplets. These droplets are rapidly dried by hot air flow, yielding uniform particles ideal for powder production in industries such as food, pharmaceuticals, and chemicals.Q: What can be processed using this spray drying system?

A: This system is designed for applications across pharmaceuticals, food, dairy, ceramics, chemicals, and dye industries, converting liquid or slurry materials into consistent powders suitable for consumption, formulation, or manufacturing.Q: When should spray pressure and inlet air temperature be adjusted?

A: Adjust spray pressure (27 bar) and inlet air temperature (160C350C) based on the material properties and desired powder quality. Higher pressures and temperatures improve drying efficiency for viscous materials, while sensitive substances may require gentler settings.Q: Where can this system be installed and operated?

A: The modular or skid-mounted design enables installation in a variety of industrial settingsincluding factories or processing plantsacross India and globally. Dimensions and capacity are customizable to fit facility requirements.Q: What benefits does the system offer over traditional drying methods?

A: Spray drying delivers rapid, uniform particle formation from liquids and slurries, minimizing thermal degradation and retaining product quality. The systems automatic PLC control, efficient exhaust filtration, and clean-in-place features further enhance operation and maintenance.Q: How does the safety protection in the system operate?

A: Safety features such as overload, over-temperature sensors, and interlock systems monitor operation, automatically intervening to prevent accidents or damage, ensuring continuous, reliable performance during powder production.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese